Outdoor Research

Mechanical Engineer II – OR Pro

OR Pro is Outdoor Research’s tactical division, designing and manufacturing technical outerwear and accessories for the U.S. military and first responders. OR Pro’s flagship product, the Cold Weather Glove System (CWGS), includes the only Gore-Tex approved, waterproof mitt that uses a seam-sealed construction, allowing for a superior fitting and performing product. Other products made in-house include the Expedition Crocodile Gaiter and the SG Water Bottle Parka.

As a Mechanical Engineer in OR’s El Monte, California production facility I am responsible for sharing, contributing, and executing the vision of the factory through continuous improvements in process, cost, safety, and quality. I have worked on manufacturing line layouts, automated machinery design, product re-designs, manufacturing aids, and new product design. Through my close collaboration with the production associates, I have received a “master class” in user experience, as many of my implementations are interacted with 8 hours a day, 5 days a week.

CWGS Mitts

Fully automated sewing machine used to fold, sew, and cut to length a strip of rip stop fabric.

Adjustable sewing feed plate used in conjunction with special clamping arms on a CNC sewing machine to attache velcro to straps.

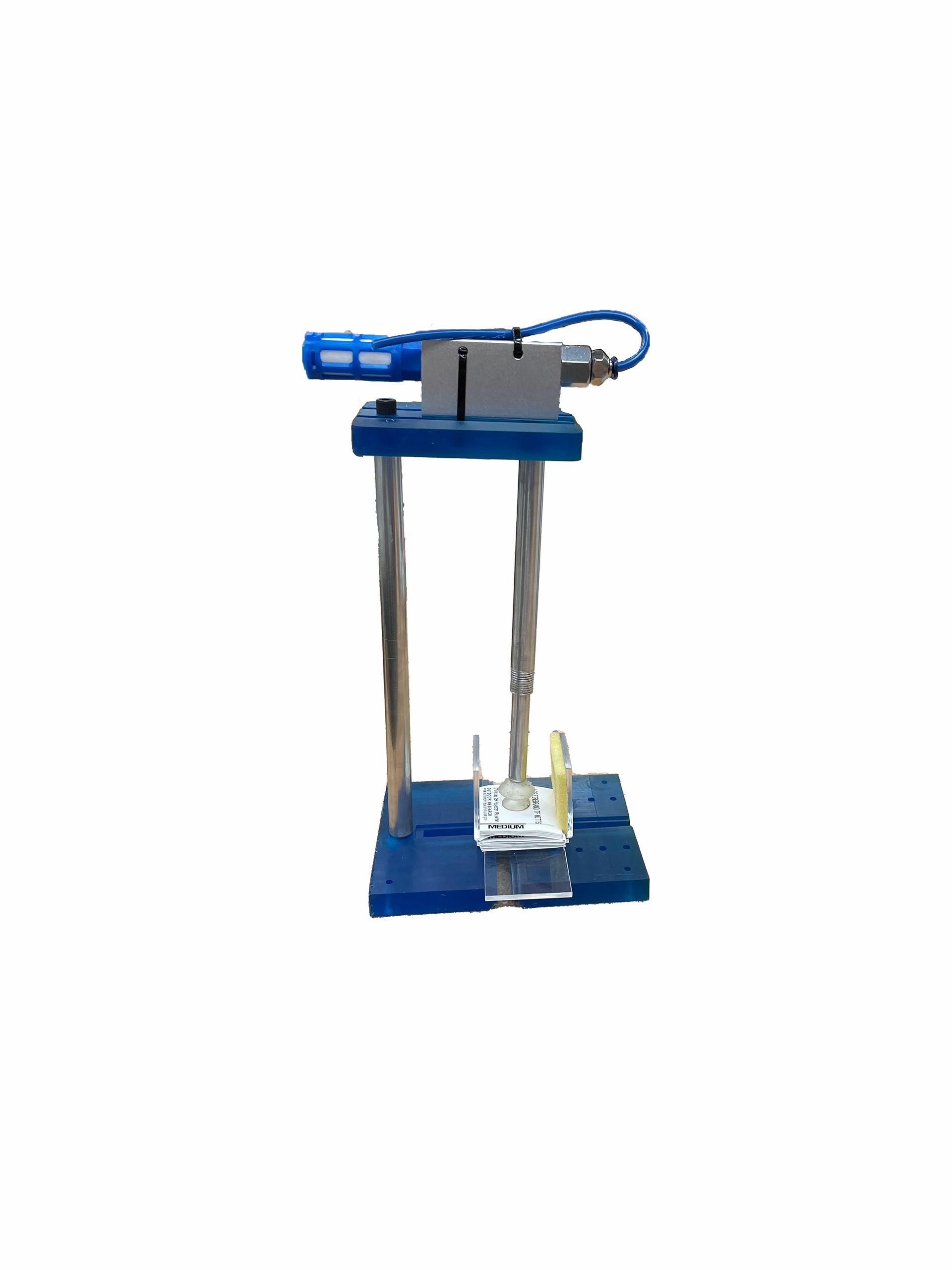

Custom Label Picker. This device uses a vacuum effector to present otherwise hard to pick up labels to production associates. Reduced the cost to implement such devices by $550 to ~$50 when compared to off-the-shelf pickers.

Goat Leather, Waterproof Pocket Liner, and Touch Tec Leather joined using a custom CNC sewing jig.

Cell Based Manufacturing Line

I run the CNC sewing program consisting of 15 machines, including the Brother 342H pictured here.

The automated sewing machine in action!

Two-Staged Clamp and Modified Feed Plate for user-friendly addition of a buckle.